- Facility comprises of effective combination of Mechanical and Manual Segregation.

- Low initial capital investment and O&M cost.

- Easy to operate and maintain.

- Greater flexibility on processing capacity.

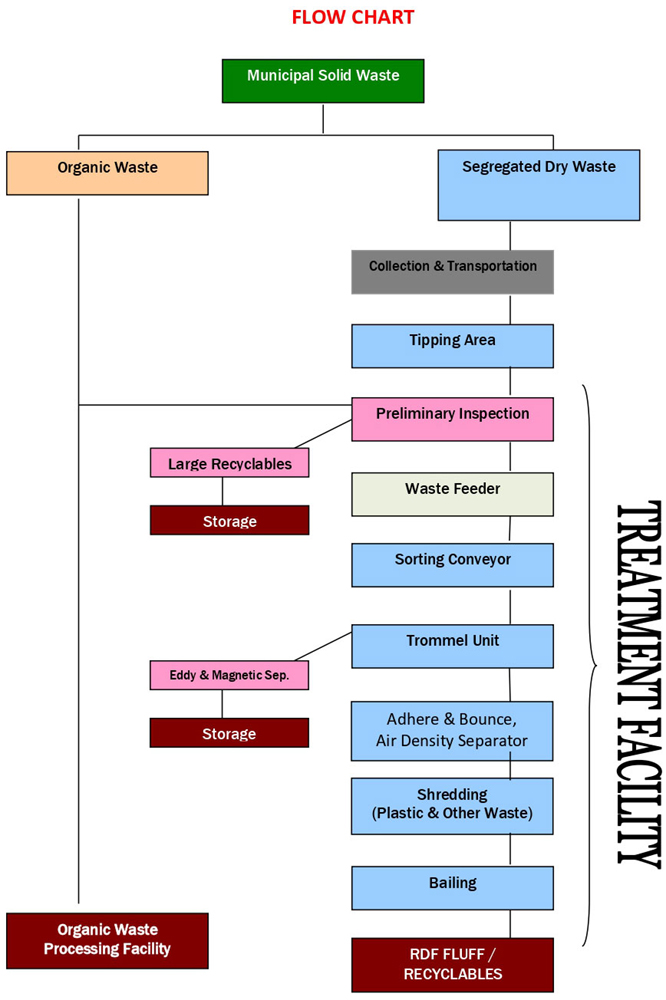

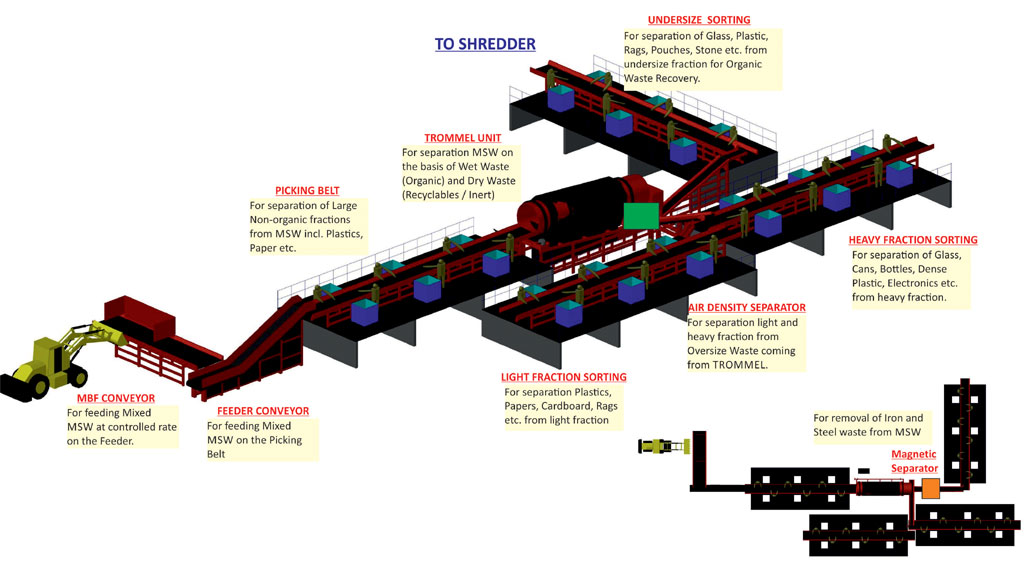

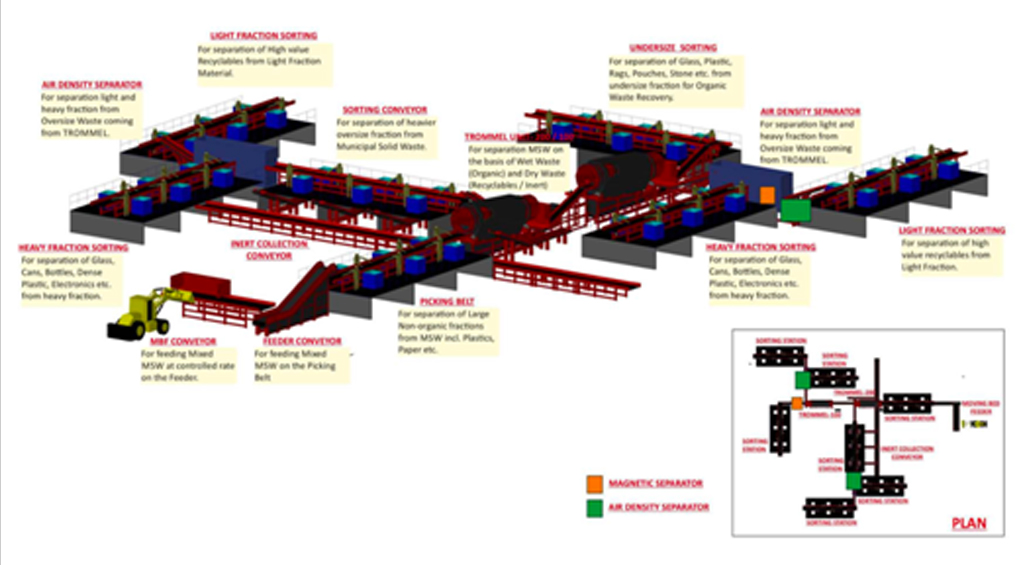

Material Recovery Facility is specifically designed to segregate Dry Municipal Waste into different recyclable and non-recyclable fractions. Waste material like Glass, Paper, Plastics, Metals etc. , all are segregated using a combination of Mechanical and Manual Separation process. Segregation of even Mixed Municipal Solid Waste with Dry and Wet both types of Waste, mixed together, is also possible in Material Recovery Facility.

Specification

| S.No. | EQUIPMENTS | QTY. | PURPOSE |

| 1 | Moving Bed Feeder | 1 No. | For feeding the Dry Waste at a pre-specified rate to the Feeder Conveyor. |

| 2 | Feeder Conveyor | 1 No. | For dumping the Dry Waste at a pre-specified rate onto the Sorting Conveyor. |

| 3 | Sorting Conveyor | 1 No. | For Sorting Dry Waste and removal of large objects. |

| 4 | Trommel along with its associated Undersize Conveyors. | 1 Set. | For loosening and segregation of Dry Waste. |

| 5 | Undersize Conveyor (Fines) with Magnetic Pulley | 1 No. | For removal of dust and dirt coming with the Dry waste along with small sized Iron. |

| 6 | Adhere and Bounce Conveyor | 1 No. | For Separation of light and heavier rollable fraction from the Mixed Municipal Solid Waste. |

| 7 | Air Density Separator with Sorting Conveyors – 2 Nos. | 1 Set | For separation of light and heavy fraction followed by Manual Sorting. |

| 8 | Magnetic Separator | 1 No. | For Separation of Magnetic Metals from the Dry Waste. |

| 9 | Eddy Current Separator | 1 No. | For Separation of Non-Magnetic Metals from the Dry Waste. |

| 10 | Sorting Conveyor | 2 No. | For Sorting Dry Waste and recovery of various recyclables and combustible material. |

Product Gallery

Benefits & Features

Video Gallery